Table of Contents

Astronauts in space are about to become more self-sufficient.

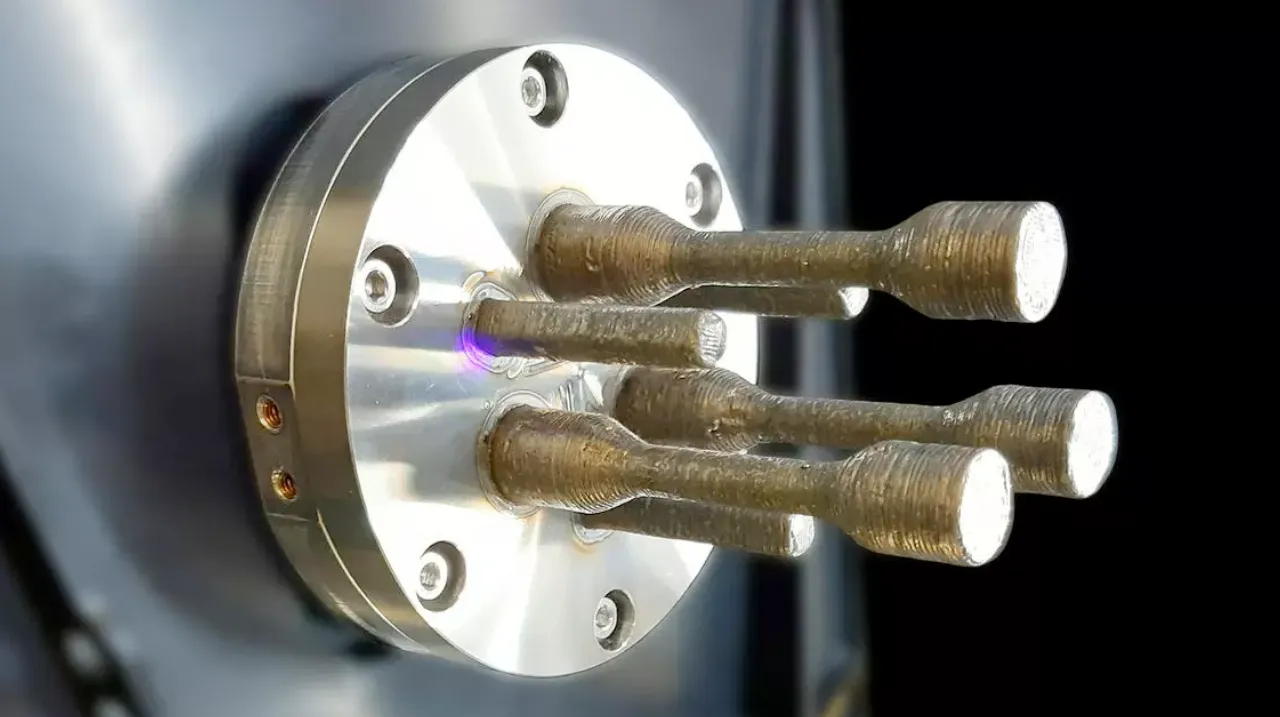

The European Space Agency (ESA) recently launched the first-ever 3D metal printer into space aboard NASA’s NG-20 mission. The 3D printer will allow astronauts to make several kinds of complex metal structures in space, ranging from basic components like nuts and bolts to essential tools such as wrenches, marking a significant leap in how astronauts live and work.

Weighing 180 kg, the 3D printer was developed by an ESA-funded consortium led by Airbus Defense and Space, along with AddUp, Cranfield University, and Highftech Engineering, and will be installed on the Columbus module of the International Space Station (ISS).

Once there, it’ll be remotely operated and monitored by researchers from Earth…

- The first demonstration project involves printing four metal shapes, each no larger than a soda can and weighing under 250 grams. It will take the machine about two to four weeks to print each object.

- The printed items will be returned to Earth where researchers will analyze each part’s mechanical strength and microstructure. The objects will also be compared to reference shapes that are 3D printed on Earth.

Zoom out: This project is just the opening act of a bigger vision - enabling sustainable human presence on the Moon. This project will help researchers better understand how to build and maintain metal structures in the vacuum of space, so when the time is right, technology will exist to enable manufacturing on the Moon.

Gwenaëlle Aridon, Airbus's lead engineer, shared her vision: “Thinking beyond the ISS, the applications could be amazing. Imagine a metal printer using transformed moondust or recycled materials to build a lunar base.”